Global Metals Industries is a leading supplier, exporter, and stockist of premium quality Gaskets in India. Known for superior performance, our gaskets are widely used in industries requiring excellent sealing, corrosion resistance, durability, and heat resilience. With decades of expertise, we deliver products that meet stringent international standards.

We cater to diverse industrial requirements across shipbuilding, chemical processing, aerospace, power generation, oil & gas, and sugar mills. With a strong distribution network covering India and exports to over 26 countries, Global Metals Industries has established itself as a reliable global partner for gasket solutions.

Manufactured using cutting-edge technology, advanced machinery, and high-quality raw materials, our gaskets undergo multiple quality checks including chemical, mechanical, and PMI testing. This ensures leak-proof, defect-free performance in the most demanding environments.

\

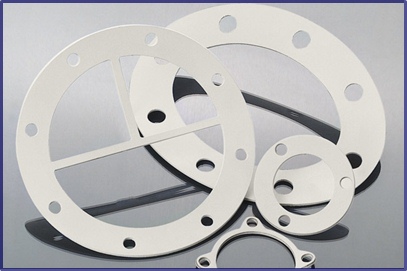

\Manufactured from high-quality PTFE material, offering excellent chemical resistance, non-contamination, and high-temperature tolerance. Widely used in the chemical, pharmaceutical, and food processing industries.

\

\Flexible and versatile gaskets designed for excellent sealing, especially in applications involving irregular or damaged flange surfaces. Provides superior resistance to aggressive chemicals and extreme temperatures.

\

\Precision-engineered metallic gaskets designed to withstand high-pressure and high-temperature environments. Commonly used in oil & gas, petrochemical, and refinery industries.

\

\Custom-cut gaskets available in various shapes and materials to suit diverse industrial requirements. Ideal for general sealing applications across multiple industries.

\

\Designed to prevent galvanic corrosion and provide electrical isolation in piping systems. Widely used in oil & gas pipelines and marine applications.

\

\Made by winding metallic strips with filler materials, offering exceptional strength and reliability under extreme pressure and temperature conditions. Suitable for critical applications in refineries and chemical plants.

| Specification | Details |

|---|---|

Size | Available from ½” NB – 24” NB |

Class | Standard, Special, and Limited. ASME B16.34 covers Class 150, 300, 400, 600, 900, 1500, 2500, and 4500 valves |

Standards | ASME B16.20 Gaskets |

Materials | Stainless Steel, Low Carbon Steel, Carbon Steel, 4–6% Chrome ½% Moly, Alloy 20, Hastelloy B2, Hastelloy C276, Incoloy 800, Inconel 600, Inconel X750, Monel 400, Nickel 200, Titanium |

Outside Diameter | Tolerance for NPS ½ through NPS 8: ±0.8 mm; for NPS 10 through NPS 24: +1.5 mm, −0.8 mm |

Inside Diameter | Tolerance for NPS ½ through NPS 8: ±0.4 mm; for NPS 10 through NPS 24: ±0.8 mm |

Thickness | Tolerance ±0.13 mm measured across the metallic portion of the gasket (filler may extend slightly beyond the metal) |

Type | Compressed Non-Asbestos Fiber, PTFE, Rubber, Mica, and Ceramic Fiber |

Delivery Condition | Annealed and Pickled, Polished, Bright Annealed, Cold Drawn |

Inspection, Test Reports | Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Reports, Non-Destructive Test Reports |

Packing | Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customer Requests |

Specials | Non-standard sizes and specifications can be manufactured on request |

Premium Metal Solutions

Mr. Amrut Kumar

8141454675

Mr. Bharat Kumar

8140094965

sales@globalmetals-industries.com

Address

Ground , Survey no- 139, Municipality no -109, Nani kadiyawad, Dariyapur gate, Vadigam, Ahmedabad, Gujarat , 380001

Quality Assured

Fast Delivery

Certified