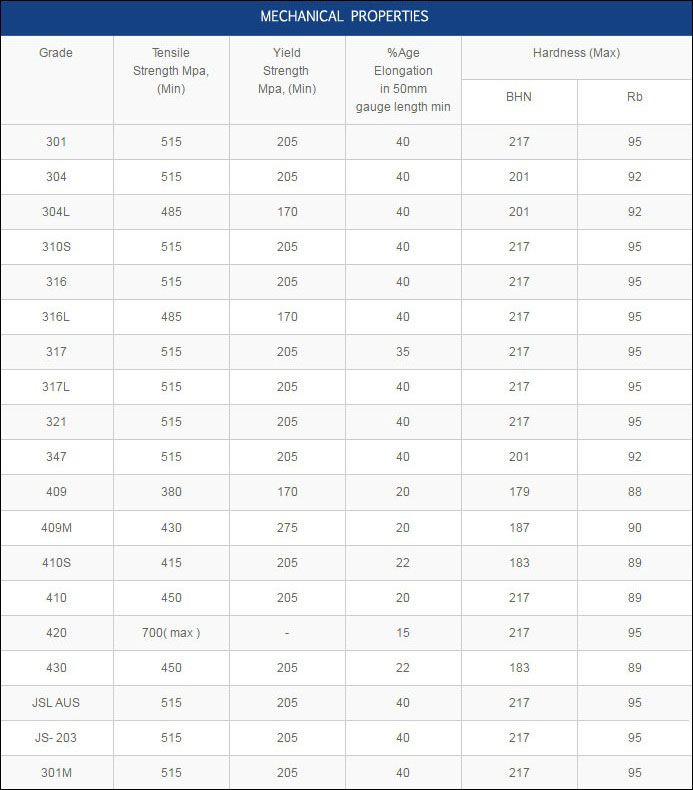

Detailed chemical composition data for various industrial alloys

Standard stainless steel compositions

| Material type | Cr | Ni | Mo | Mn | C | Si | P | S | N | Fe | Others |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 301 | 16.00-18.00 | 6.00-8.00 | - | 2.00 | 0.15 | 1.00 | 0.045 | 0.030 | 0.10 | Bal | - |

| 304 (1.4301) | 18.00-20.00 | 8.00-10.50 | - | 2.00 | 0.08 | 0.75 | 0.045 | 0.030 | 0.10 | Bal | - |

| 304L (1.4307) | 18.00-20.00 | 8.00-12.00 | - | 2.00 | 0.030 | 0.75 | 0.045 | 0.030 | 0.10 | Bal | - |

| 310S | 24.00-26.00 | 19.00-22.00 | - | 2.00 | 0.08 | 1.50 | 0.045 | 0.030 | - | Bal | - |

| 316 (1.4401) | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 | 2.00 | 0.08 | 0.75 | 0.045 | 0.030 | 0.10 | Bal | - |

| 316L (1.4404) | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 | 2.00 | 0.030 | 0.75 | 0.045 | 0.030 | 0.10 | Bal | - |

| 317 | 18.00-20.00 | 11.00-14.00 | 3.00-4.00 | 2.00 | 0.08 | 0.75 | 0.045 | 0.030 | 0.10 | Bal | - |

| 317L (1.4438) | 18.00-20.00 | 11.00-15.00 | 3.00-4.00 | 2.00 | 0.030 | 0.75 | 0.045 | 0.030 | 0.10 | Bal | - |

| 321 (1.4541) | 17.00-19.00 | 9.00-12.00 | - | 2.00 | 0.08 | 0.75 | 0.045 | 0.030 | 0.10 | Bal | Ti5(C+N) Min or 0.70 max |

| 347 (1.4550) | 17.00-19.00 | 9.00-13.00 | - | 2.00 | 0.08 | 0.75 | 0.045 | 0.030 | - | Bal | Cb=10x(C Min) or 1.00 Max |

| 409 | 10.50-11.75 | 0.50 | - | 1.00 | 0.08 | 1.00 | 0.040 | 0.010 | - | Bal | Ti=6x(C+N) Min or 0.70 Max |

| 409M | 11.00-12.00 | 1.5 max | - | 0.8-1.2 | 0.03 | 0.4-0.75 | 0.030 | 0.030 | - | Bal | Ti=6x(C) Min or 0.70 Max |

| 410S | 11.50-13.50 | 0.60 | - | 1.00 | 0.08 | 1.00 | 0.040 | 0.030 | - | Bal | - |

| 410 (1.4006) | 11.50-13.50 | 0.75 | - | 1.00 | 0.15 | 1.00 | 0.040 | 0.030 | - | Bal | - |

| 420 (1.4021) | 12.00-13.00 | 0.2-0.3 | - | 0.50 | 0.35 | 0.50 | 0.035 | 0.015 | - | Bal | - |

| 430 (1.4016) | 16.00-18.00 | 0.75 | - | 1.00 | 0.12 | 1.00 | 0.040 | 0.030 | - | Bal | - |

| JSL AUS | 15.50-16.50 | 4.25-4.75 | - | 7.0-8.0 | 0.08 | 0.75 | 0.070 | 0.030 | - | Bal | Cu: 0.9-1.10 |

| JS-203 | 14.25-15.25 | 2.25-2.75 | - | 9.25-10.25 | 0.08 | 0.75 | 0.070 | 0.030 | - | Bal | Cu: 1.60-2.0 |

| 301M | 14.50-15.50 | 6.0-7.0 | - | 4.5-5.5 | 0.10 | 0.75 | 0.060 | 0.030 | - | Bal | Cu: 1.70-1.90 |

| 440C (1.4125) | 16.00-18.00 | 0.75 | 0.75 | 1.00 | 0.95-1.20 | 1.00 | 0.040 | 0.030 | - | Bal | - |

| 904L (1.4539) | 19.00-23.00 | 23.00-28.00 | 4.00-5.00 | 2.00 | 0.02 | 1.00 | 0.045 | 0.035 | - | Bal | Cu: 1.00-2.00 |

| 17-4PH (1.4542) | 15.00-17.50 | 3.00-5.00 | - | 1.00 | 0.07 | 1.00 | 0.040 | 0.030 | - | Bal | Cu: 3.00-5.00, Nb: 0.15-0.45 |

| 15-5PH (1.4545) | 14.00-15.50 | 3.50-5.50 | - | 1.00 | 0.07 | 1.00 | 0.040 | 0.030 | - | Bal | Cu: 2.50-4.50 |

| Duplex 2205 (1.4462) | 21.00-23.00 | 4.50-6.50 | 2.50-3.50 | 2.00 | 0.03 | 1.00 | 0.035 | 0.020 | 0.14-0.20 | Bal | - |

| Super Duplex 2507 (1.4410) | 24.00-26.00 | 6.00-8.00 | 3.00-5.00 | 1.20 | 0.03 | 0.80 | 0.035 | 0.020 | 0.24-0.32 | Bal | Cu: 0.50 |

| 254 SMO (1.4547) | 19.50-20.50 | 17.50-18.50 | 6.00-7.00 | 1.00 | 0.02 | 0.80 | 0.030 | 0.010 | 0.18-0.22 | Bal | Cu: 0.50-1.00 |

| Alloy 20 (2.4660) | 19.00-21.00 | 32.00-38.00 | 2.00-3.00 | 2.00 | 0.07 | 1.00 | 0.045 | 0.035 | - | Bal | Cu: 3.00-4.00, Nb: 8xC-1.00 |

| 309 (1.4828) | 22.00-24.00 | 12.00-15.00 | - | 2.00 | 0.20 | 1.00 | 0.045 | 0.030 | - | Bal | - |

Standard nickel-based alloy compositions

| Material type | Ni | Cr | Co | Mo | W | Fe | Al | Ti | Cu | Nb | Other |

|---|---|---|---|---|---|---|---|---|---|---|---|

| - | - | - | - | - | - | - | - | - | - | - | - |

| Hastelloy A | 57.00 | 1.0* | - | 21.00 | - | 19.00 | - | - | - | - | - |

| Hastelloy B | 62.00 | 1.0* | 2.5* | 28.00 | - | 5.50 | - | - | - | - | 0.4% V |

| Hastelloy D | 85.00 | 1.0* | - | - | - | 1.0* | - | - | 4.0* | - | 9% Si |

| Hastelloy F | 45.00 | 22.00 | 2.5* | 6.00 | 1.0* | 18.00 | - | - | - | 2.00 | - |

| Hastelloy G | 44.00 | 22.00 | - | 6.50 | 1.0* | 20.00 | - | - | 2.00 | 2.00 | - |

| Hastelloy N | 72.00 | 7.00 | 0.20 | 16.50 | 0.50 | 5.0* | 0.25 | 0.25 | - | - | 0.01% B |

| Hastelloy R | 66.00 | 15.50 | 1.5* | 5.00 | - | 7.0* | 2.20 | 2.50 | - | - | - |

| Hastelloy S | 68.00 | 15.50 | - | 14.50 | - | 1.00 | - | - | - | - | 0.5%Mn 0.4% Si |

| Hastelloy W | 63.00 | 5.00 | 2.5* | 24.50 | - | 5.50 | - | - | - | - | 0.6% V |

| Hastelloy X | 47.00 | 22.00 | 1.50 | 9.00 | 0.60 | 18.50 | - | - | - | - | - |

| Hastelloy C276 | 56.00 | 16.00 | 2.5* | 17.00 | 4.00 | 5.50 | 0.4* | - | - | - | 0.35% V |

| Hastelloy C22 | 54.00 | 21.00 | 2.5* | 14.00 | 3.00 | 5.0* | 0.4* | - | - | - | 0.35% v |

| Hastelloy C4 | 54.00 | 16.00 | 1.25* | 16.00 | - | 2.0* | 0.4* | 0.5* | - | - | - |

| Inconel 600 | 75.50 | 15.50 | - | - | - | 7.00 | - | - | - | - | - |

| Inconel 601 | 60.50 | 23.00 | - | - | - | 14.10 | 1.35 | - | - | - | - |

| Inconel 702 | 79.00 | 15.60 | - | - | - | 0.40 | 3.40 | 0.70 | - | - | - |

| Inconel 713C | 72.00 | 13.40 | - | 4.50 | - | 1.5* | 6.20 | 1.0* | - | 2.30 | - |

| Inconel 718 | 53.00 | 18.50 | - | 3.00 | - | 18.00 | - | 0.80 | - | 5.00 | - |

| Inconel 800 | 32.00 | 20.00 | - | - | - | 47.00 | - | - | - | - | - |

| Inconel 825 | 40.00 | 21.00 | - | 3.00 | - | 32.00 | - | 1.00 | 2.00 | - | - |

| Inconel 901 | 42.00 | 12.50 | 1.0* | 5.70 | - | 35.00 | 0.35* | 2.90 | - | - | - |

| Inconel 792 | 61.00 | 12.50 | 9.00 | 2.00 | 3.90 | - | 3.20 | 4.20 | - | - | 4.2% Ta/ 1% Hf |

| Inconel 738 | 61.00 | 16.00 | 8.50 | 1.75 | 2.60 | 0.50 | 3.40 | 3.40 | - | 0.90 | 1.75% Ta |

| Inconel 939 | 48.00 | 22.40 | 19.00 | - | 2.00 | - | 1.90 | 3.70 | - | 1.00 | 1.4% Ta |

| GMR 235 | 63.00 | 15.50 | - | 3.20 | - | 10.00 | 3.70 | 2.00 | - | - | 0.06% B |

| Nimonic 75 | 77.00 | 20.00 | - | - | - | 5.0* | 0.15 | 0.40 | - | - | - |

| Nimonic 80 | 74.00 | 20.00 | 2.0* | - | - | 1.5* | 1.30 | 2.20 | - | - | - |

| Nimonic 81 | 65.00 | 30.00 | - | - | - | 1.0* | 1.00 | 1.75 | - | - | - |

| Nimonic 90 | 57.00 | 20.00 | 16.00 | - | - | 5.0* | 1.50 | 2.50 | - | - | - |

| Nimonic 91 | 47.50 | 28.50 | 20.00 | - | - | - | 1.20 | 2.30 | - | - | - |

| Nimonic 105 | 53.00 | 15.00 | 20.00 | 5.00 | - | 1.0* | 4.70 | 1.20 | - | - | - |

| Nimonic 115 | 57.00 | 15.00 | 15.00 | 3.50 | - | 1.0* | 5.00 | 4.00 | - | - | - |

| Nimonic C263 | 50.00 | 20.00 | 20.00 | 5.90 | - | 0.75* | 0.50 | 2.20 | - | - | - |

| Nimonic C1023 | 56.00 | 15.50 | 9.50 | 8.00 | - | 0.25 | 4.30 | 3.60 | - | - | - |

| GTD 111 | 59.00 | 14.00 | 9.50 | 1.50 | 3.80 | 0.5* | 3.00 | 4.90 | - | - | 2.8% Ta/ 0.02*% B |

| GTD 222 | 50.00 | 22.50 | 19.00 | - | 2.00 | 0.25* | 1.20 | 2.30 | - | 0.80 | 1.0% Ta |

| Rene 41 | 52.00 | 19.00 | 11.00 | 10.00 | - | 5.0* | 1.60 | 3.20 | - | - | - |

| Rene 77 (Udimet 700) | 52.00 | 15.00 | 15.00 | 4.00 | - | 0.5* | 4.20 | 3.50 | - | - | 0.02*% B |

| Rene 80 | 60.00 | 14.00 | 9.50 | 4.00 | 4.00 | - | 3.00 | 5.00 | - | - | - |

| Rene 88 | 55.00 | 16.00 | 13.00 | 4.00 | 4.00 | 0.25 | 2.10 | 3.75 | - | 0.70 | 0.02% B |

| Rene 125 | 59.00 | 9.00 | 10.00 | 2.00 | - | - | 4.80 | 2.60 | - | - | 3.8% Ta/ 1.6% Hf / 7% W |

| Waspalloy | 56.00 | 19.00 | 14.00 | 4.20 | - | 1.5* | 1.40 | 3.00 | - | - | 0.1% Zr |

| Udimet 500 | 53.00 | 17.50 | 16.50 | 4.00 | - | 4.00 | 2.90 | 3.90 | - | - | 0.01 B |

| Udimet 520 | 56.00 | 19.00 | 12.00 | 6.00 | 1.00 | 1.00 | 2.00 | 3.00 | - | - | - |

| Udimet 600 | 52.00 | 17.50 | 16.50 | 4.00 | - | 4.0* | 4.20 | 2.90 | - | - | 0.04*% B |

| Mar M 246 | 600.00 | 9.00 | 10.00 | 2.50 | 10.00 | 0.15 | 5.50 | 1.50 | - | - | 1.5% Ta |

| PWA 663 (B1900) | 64.00 | 8.00 | 10.00 | 6.00 | - | - | 6.00 | 1.00 | - | - | 1% Zr/ 4% Ta |

| Mar M 200 | 60.00 | 9.00 | 10.00 | - | 12.00 | - | 5.00 | 2.00 | - | 1.00 | 0.12% B |

| Mar M 002 | 59.00 | 10.00 | 10.00 | - | 10.00 | 1.0* | 5.00 | 1.50 | - | - | 2.5% Ta / 1.5% Hf |

| Mar M 247 | 58.00 | 8.50 | 10.00 | 0.60 | 10.00 | 0.5* | 5.50 | 1.00 | - | - | 3% Ta |

| Alloy 230 | 57.5 | 22.00 | - | 2.00 | 14.00 | 3 | 0.30 | - | - | - | 0.1% C/0.5% Mn/0.4% Si |

| Kovar | 29 | - | 17 | - | 54 | - | - | - | - | - | - |

| N155 (Multimet) | 20 | 21 | 20 | 3 | 2.5 | 30.35 | - | - | - | - | 0.5% C/ Ta 1%/ Si 0.5% |

High-performance nickel-based alloy compositions

| Material type | Ni | Cr | Co | Mo | W | Nb | Ta | Ti | Re | Hf | Other |

|---|---|---|---|---|---|---|---|---|---|---|---|

| PWA 1480 | Bal | 10 | 5 | - | 4 | - | 12 | 1.5 | - | - | B-0.003%/ Al 5% |

| PWA 1484 | Bal | 5 | 10 | 1.9 | 5.9 | - | 8.7 | - | 3 | 0.1 | Al 5.6% |

| PWA 1487 | Bal | 5 | 10 | 1.9 | 5.9 | - | 8.4 | - | 3 | 0.25 | Al 5.65% |

| Rene N4 | Bal | 10 | 8 | 2 | 6 | 0.5 | 5 | 3.5 | - | 0.2 | Al 4.2% |

| Rene N5 | Bal | 7 | 8 | 2 | 5 | - | 6 | - | 3 | 0.2 | Al 6.2% |

| Rene N6 | Bal | 4 | 12 | 1 | 6 | - | 7 | - | 5 | 0.2 | Al 5.8% |

| CMSX-2 | Bal | 8 | 5 | 0.6 | 8 | - | 6 | 1 | - | - | Al 5.6% |

| CMSX-3 | Bal | 8 | 5 | 0.6 | 8 | - | 6 | 1 | - | 0.1 | Al 5.6% |

| CMSX-4 | Bal | 6.5 | 9 | 0.6 | 6 | - | 6.5 | 1 | 3 | 0.1 | Al 5.6% |

| CMSX-6 | Bal | 10 | 5 | 3 | - | - | 2 | 4.7 | - | 0.1 | Al 4.8% |

| CMSX-10 | Bal | 2 | 3 | 0.4 | 5 | 0.1 | 8 | 0.2 | 6 | 0.03 | Al 5.7% |

| CMSX 486 | Bal | 5 | 9 | 0.7 | 9 | - | 4.5 | 0.7 | 3 | 1 | C 0.07%/ Al 5.7%/ B 0.015%/ Zr 0.005% |

High-performance cobalt-based alloy compositions

| Material Type | Co | Cr | Ni | W | Mo | C | Fe | Al | B | Cu | Ta | Others |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stellite® 4 | 53.00 | 31.00 | 3.0* | 14.00 | 1.5* | 1.0* | 3.0* | - | - | - | - | 1% Mn/ 1.5% Si |

| Stellite® 6 | 66.00 | 30.00 | 3.0* | 4.50 | 1.5* | 1.10 | 3.0* | - | - | - | - | - |

| Stellite® 8 (F75) | 63.00 | 30.00 | - | - | 6.25 | 0.25 | - | - | - | - | - | 0.45% Mn/ 0.6% Si |

| Stellite® 12 | 59.00 | 30.00 | 3.0* | 9.00 | - | 1.50 | 3.0* | - | - | - | - | 1% Mn/ 1% Si |

| Stellite® 19 | 52.00 | 31.00 | 3.0* | 10.50 | - | 0.70 | 3.0* | - | - | - | - | 1% Mn/ 1% Si |

| Stellite® 21 | 60.00 | 27.00 | 2.5* | - | 5.50 | 0.25 | 3.0* | - | 0.01 | - | - | 1% Mn/ 1% Si |

| Stellite® 25 (L605) | 52.00 | 20.00 | 10.00 | 15.00 | - | 0.15* | 2.00* | - | - | - | - | - |

| Stellite® 30 | 50.00 | 26.00 | 15.00 | - | 6.00 | 0.45* | 2.0* | - | - | - | - | 0.3% Mn/ 0.6% Si |

| Stellite® 31 (X40) | 56.00 | 25.00 | 10.00 | 7.00 | - | 0.50 | - | - | - | - | - | 0.6% Mn/ 0.5% Si |

| Stellite® X45 | 56.00 | 25.00 | 10.50 | 7.50 | 0.5* | 0.3* | 2.0* | - | 0.02 | - | - | - |

| Stellite® 188 | 37.00 | 22.00 | 22.00 | 14.00 | - | 0.10 | 3.0* | - | - | - | - | 1.25% Mn |

| Elgiloy | 40.00 | 20.00 | 15.00 | - | 7.00 | 0.15 | 17.00 | - | - | - | - | 0.04% Be |

| Umco 50 | 50.00 | 28.00 | - | - | - | 0.12 | 20.00 | - | - | - | - | 0.5% Mn/ 0.75% Si |

| Umco 51 | 48.00 | 28.00 | - | - | - | - | 20.00 | - | - | - | - | 2% Nb/ 0.7% Si |

| Mar M 509 | 50.00 | 23.50 | 10.00 | 7.00 | - | 0.60 | 2.0* | - | - | - | - | Ta- 3.5%/ Ti 0.2%/ Zr 0.5% |

| FSX 414 | 48.00 | 30.00 | 10.50 | 7.00 | - | 0.3* | 1.5* | - | 0.015* | - | - | - |

| MP35N | 35.00 | 20.00 | 35.00 | - | 10.00 | - | - | - | - | - | - | - |

| MP159 | 35.00 | 19.00 | 25.00 | - | 7.00 | - | 9.00 | 0.20 | - | - | - | Ti 3%/ Cb 0.6% |

| WI-52 | - | 21.00 | 1.00 | 11.00 | - | 0.45 | 2.00 | - | - | - | - | 2% Cb/ 0.5% Mn/ 0.5% Si |

Specialized cobalt-iron alloy compositions

| Cobalt Iron Alloys | Co | Cr | Ni | W | Mo | C | Fe | Al | B | Cu | V | Others |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Permendur | 50.00 | - | - | - | - | - | 49.60 | - | - | - | - | 0.4% Mn |

| Permendur 2V (Hiperco 50) | 48.50 | - | - | - | - | - | 49.5 | - | - | - | 10 | V-2% |

| Hyperco | 35 | 1 | - | - | - | - | 63 | - | - | - | - | - |

| Hyperco 50 | 49 | - | - | - | - | - | 48 | - | - | - | 2 | - |

| Hyperco 35 | 35 | 0.5* | 0.3* | - | - | - | 63 | - | - | - | - | - |

| Hyperco 27 | 27 | - | - | - | 0.3* | - | 71 | - | - | - | 0.5* | 0.3%* Mn |

| Hyperco 27 2v | 27 | - | - | - | - | - | 70 | - | - | - | 2 | - |

| Vicalloy | 52 | - | - | - | - | - | 38 | - | - | - | - | - |

Specialized tungsten-based alloy compositions

| Material type | W | Ni | Cu | Fe | Co | C | Others |

|---|---|---|---|---|---|---|---|

| Mallory 1000 | 90.00 | 6.00 | 4.00 | - | - | - | - |

| Mallory 2000 | 95.00 | 3.50 | 1.50 | - | - | - | - |

| Mallory 3000 | 90.00 | 7.00 | - | 3.00 | - | - | - |

| Mallory 3925 | 92.50 | 5.25 | - | 2.20 | - | - | - |

| Mallory 3950 | 95.00 | 3.50 | - | 1.50 | - | - | - |

| Mallory 3970 | 97.00 | 2.00 | - | 1* | - | - | - |

| - | - | - | - | - | - | - | - |

| Tungsten Carbide straight grade | 87.00 | - | - | - | 6.00 | 6.00 | - |

| Tungsten Carbide TiC TaC | 81.00 | - | - | - | 6.00 | 6.00 | TaC 3%/ TiC 4% |

Lightweight and corrosion-resistant alloy compositions

| Material type | Ti | Al | V | Sn | Mn | Zr | Mo | Cu | Cr | Si | Others |

|---|---|---|---|---|---|---|---|---|---|---|---|

| CP Grade 1 | Bal | - | - | - | - | - | - | - | - | - | 0.18% O2/0.20% Fe |

| CP Grade 2 | Bal | - | - | - | - | - | - | - | - | - | 0.25% O2/ 0.3% Fe |

| CP Grade 3 | Bal | - | - | - | - | - | - | - | - | - | 0.35% O2/ 0.35% Fe |

| CP Grade 4 | Bal | - | - | - | - | - | - | - | - | - | 0.5% O2/ 0.4% Fe |

| Ti 6-6-2 | Bal | 6.00 | 6.00 | 2.00 | - | - | - | - | - | - | - |

| Ti 6-2-4-2 | Bal | 6.00 | - | 2.00 | - | 4.00 | 2.00 | - | - | - | - |

| Ti 6-2-4-6 | Bal | 6.00 | - | 2.00 | - | 4.00 | 6.00 | - | - | - | - |

| Ti 3-2-5 | Bal | 3.00 | 2.50 | - | - | - | - | - | - | - | - |

| Ti 8-1-1 | Bal | 8.00 | 1.00 | - | - | - | 1.00 | - | - | - | - |

| Ti 230 | Bal | - | - | - | - | - | - | 2.50 | - | - | - |

| Ti 260 | Bal | - | - | - | - | - | - | - | - | - | 0.2% Pd |

| Ti 314 | Bal | 4.00 | - | - | 4.00 | - | - | - | - | - | - |

| Ti 315 | Bal | 2.00 | - | - | 2.00 | - | - | - | - | - | - |

| Ti 317 | Bal | 5.00 | - | 2.50 | - | - | - | - | - | - | - |

| Ti 318 | Bal | 6.00 | 4.00 | - | - | - | - | - | - | - | - |

| Ti 443 | Bal | - | 11.00 | - | - | - | - | - | 15.00 | - | - |

| Ti 550 | Bal | 4.00 | - | 2.00 | - | - | 4.00 | - | - | 0.50 | - |

| Ti 551 | Bal | 4.00 | - | 4.00 | - | - | 4.00 | - | - | 0.50 | - |

| Ti 679 | Bal | 2.25 | - | 11.00 | - | 5.00 | 1.00 | - | - | 0.20 | - |

| Ti 680 | Bal | 2.25 | - | 11.00 | - | - | 4.00 | - | - | 0.20 | - |

| Ti 684 | Bal | 6.00 | - | - | - | 5.00 | - | - | - | 0.30 | 1% W |

| Ti 685 | Bal | 6.00 | - | - | - | 5.00 | 0.50 | - | - | 0.25 | - |

| Ti 700 | Bal | 6.00 | - | - | - | 5.00 | 4.00 | 1.00 | - | 0.25 | - |

| Ti 820 | Bal | 5.50 | - | 3.50 | - | 3.00 | 0.30 | - | - | 0.30 | 1% Nb |

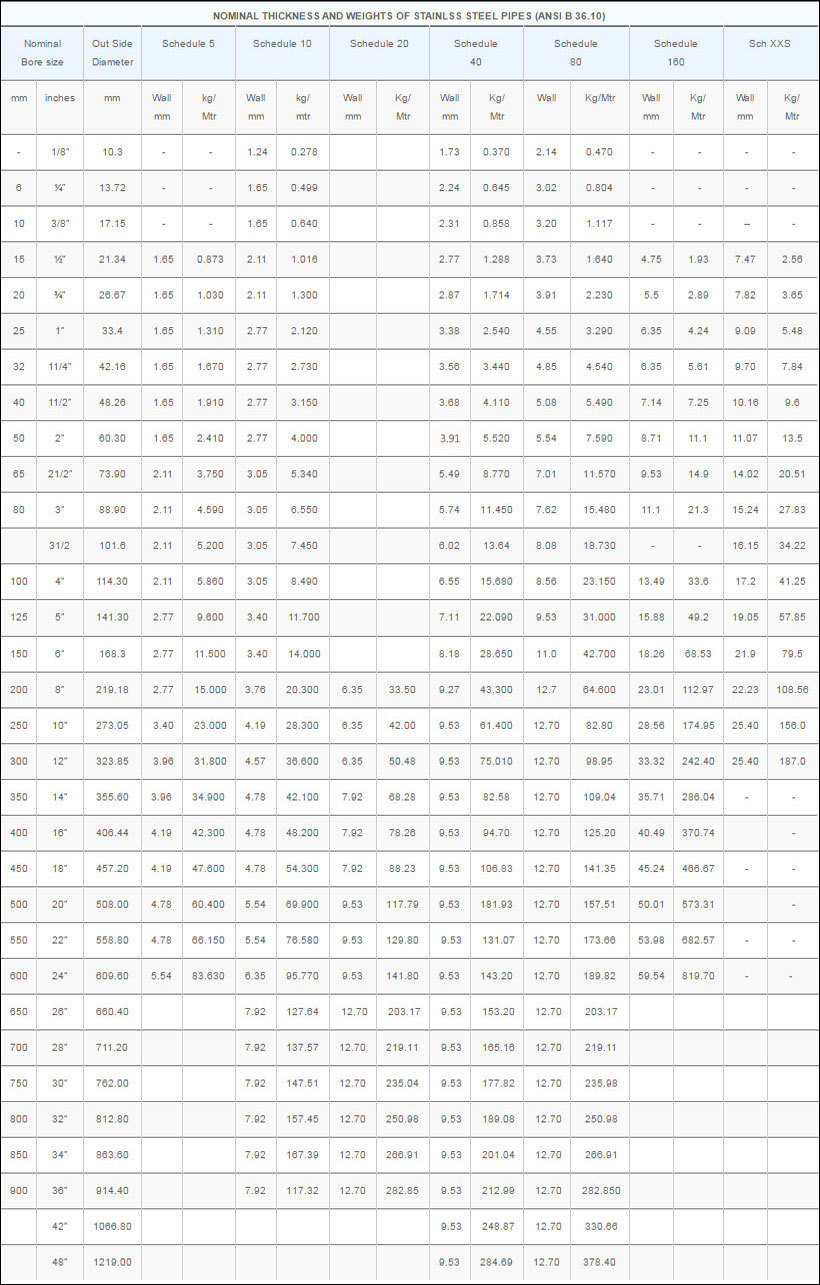

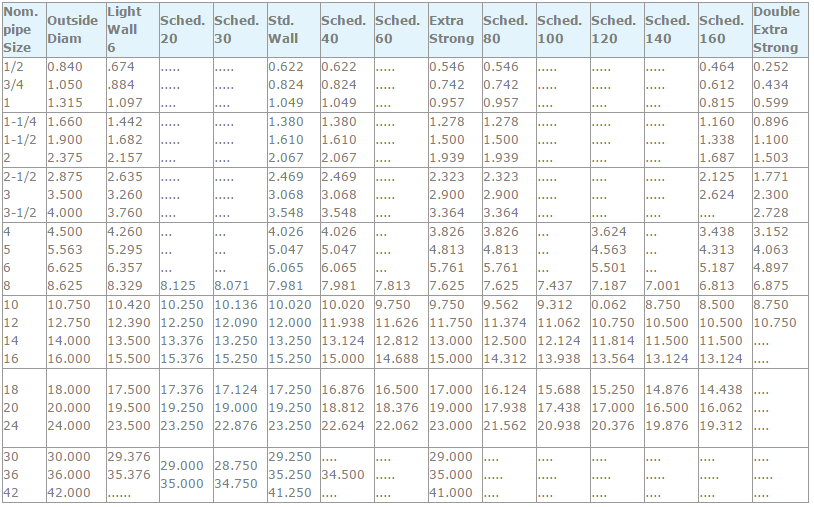

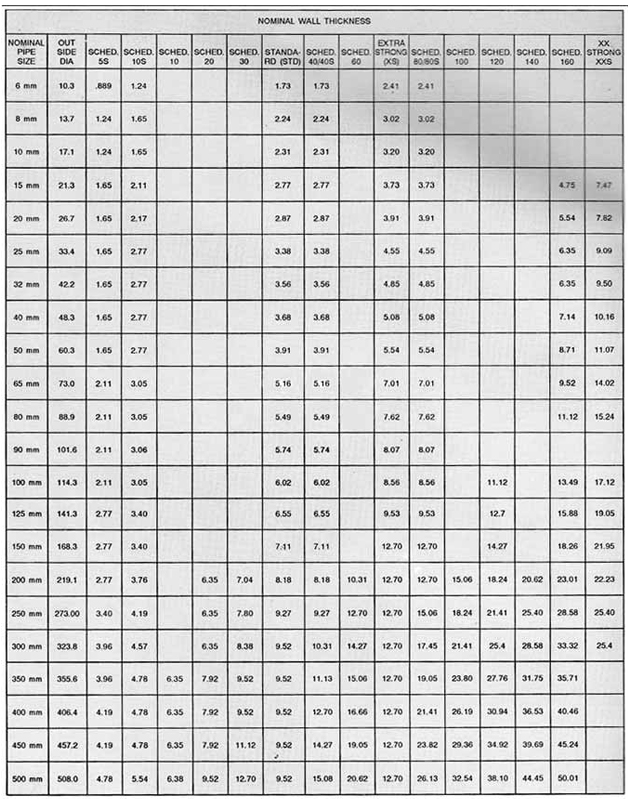

| Size: | 6mm to 500mm |

| Thickness: | Sch 5, 10, 40 |

| Specification: | 202, 304, 304L, 304H, 316, 316L, 316Ti, 321, 321H, 317, 317L, 310, 310S, 409, 410, 420, 430 |

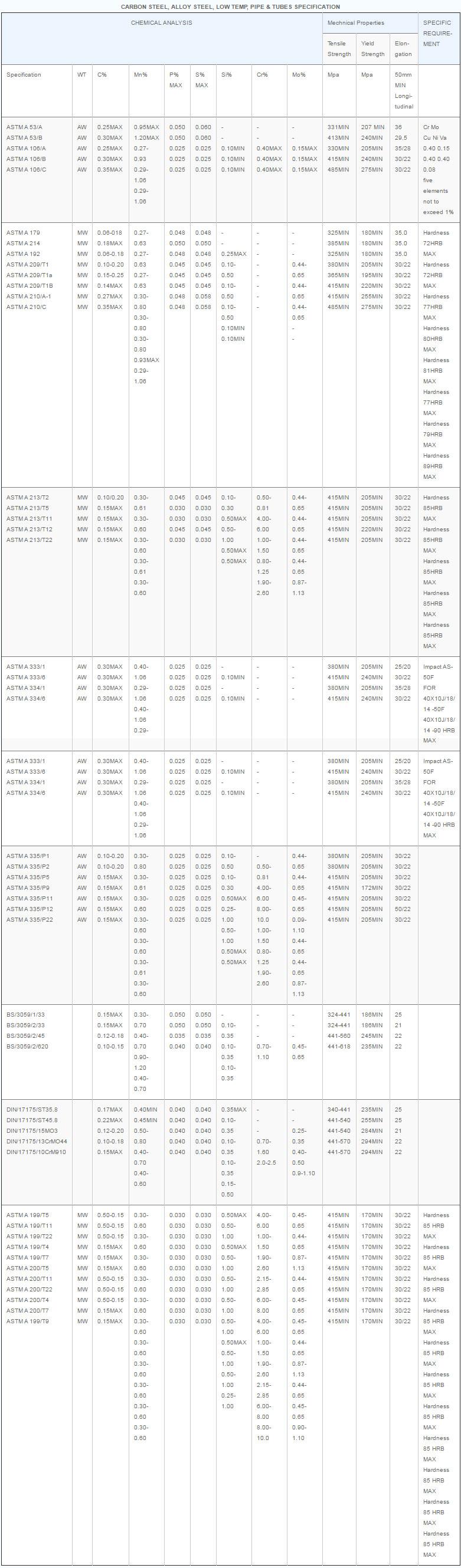

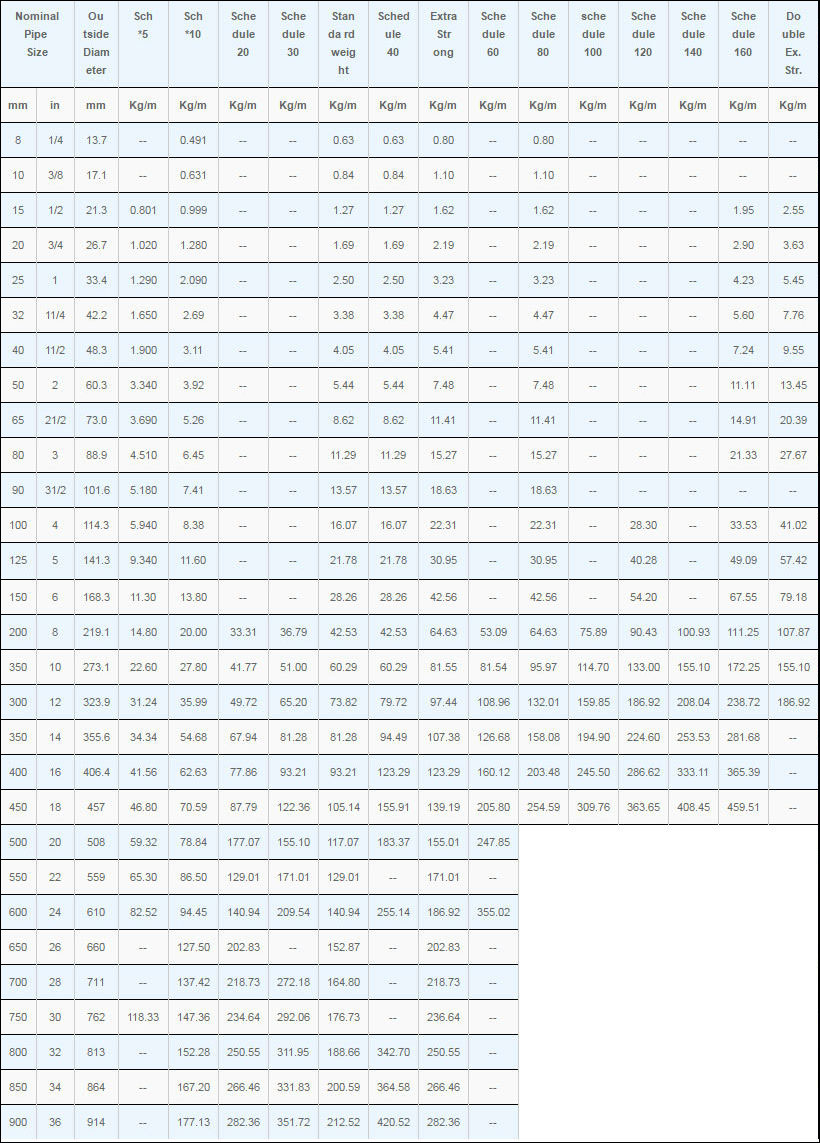

| Size: | 1/4" NB TO 24" NB IN Sch 40,60,80,120,160 & XXS. (Carbon steel) |

| Carbon Steel: | ASTM A 53, A 106, A 179, API 5L/5LX, BSS, 3059, 182, 806, 3601, 3602, DIN 17175. 2448 etc. |

| Specifications |

0.000 lbs

0.000 kgs

Dimensions

OD(mm)-W.T. (mm) x W.T.(mm)x0.02466=Kg.per Mtr.O.D.(mm) - THK(mm) x 3.14=SheetWidthLength (mtr.) x Wdth(mtr.) x Thk(mm)x8=Kg Per SheetOD(mm) x OD(mm) x Thk(mm)/160/1000=Kg Per Pcs.Dia.(mm)xdia.(mm) x 0.00623=PerMtr.Dia.(mm)xDia.(mm) x 0.00679=PerMtr.Dia.(mm)xDia.(mm) x 0.00787=PerMtr.Dia.(mm)-W.T.(mm) XW.T.(mm) x 0.02466=Kg.PerMtr.Length (mtr.) x Wdth(mtr.) x Thk(mm) x 7.85=Kg Per SheetOD(mm)-W.T. (mm) X W.T.(mm) x 0.0256=Kg.per Mtr.OD(mm)-W.T. (mm) XW.T.(mm) x 0.0345=per Mtr.Length (mtr.) XWidth(mtr.) XThk(mm) x 11.2=Kg Per SheetOD(mm)-W.T. (mm) XW.T.(mm) x 0.0082=Kg per Mtr.Length (mtr.) X Width(mtr.) X Thk(mm) x 2.66=Kg Per SheetKg/mm2 x 9.81 = N/mm2=MPaPSi x 0.0007 = Kg/mm2KSi x 1000 = PSiKg/mm2 x 1.422 = KSi